ProMat 2019 delivers thousands of manufacturing, supply chain solutions

Discover the latest solutions to move your business forward, as the industry's leading innovators showcase their latest manufacturing, distribution and supply chain equipment and systems at ProMat 2019, which took place April 8-11 at Chicago's McCormick Place.

Hosted by MHI, Charlotte, N.C., this year’s show featured innovations from over 1,000 solution providers, held more than 100 show floor seminars on emerging technologies and sustainable facility solutions and showcased hands-on demonstrations.

Here is a rundown of some of the latest innovations introduced and showcased at ProMat 2019.

Company Index

- Signode Industrial Group, LLC

- JLT Mobile Computers, Inc.

- Wildeck, Inc.

- Yale Materials Handling Corp.

- Material Handling Systems, Inc.

- Beckhoff Automation LLC

- Kardex Remstar, LLC

- Bastian Solutions

- ELOKON, Inc.

- Geek+ Robotics

- Vecna

- Storage Battery Systems LLC

- Steel King Industries, Inc.

- Dorner Mfg. Corp.

- Buemer Group

- Douglas Battery

- Patterson Fan Co.

- Teledyne DALSA

- 6 River Systems

- Adrian's Safety Solutions

- The Numina Group

- Big Ass Fans

- Zebra Technologies Corp.

- ProGlove

- Big Lift, LLC

- Sick Inc.

- Cimcorp USA, Inc.

- VanRiet Material Handling Systems

- Flexcon Container

- Feig Electronics

- IAM Robotics

- Solution Net Systems

- Commonwealth Supply Chain Advisors

- AutoGuide Mobile Robots

- Toshiba America Business Solutions Inc.

- Systems, LLC

- EVT Eye Vision Technology GmbH

- Bolzoni Auramo Inc.

- Dematic

- ASI Drives

- Thermo Fisher Scientific Product Inspection

- Regal Beloit Corp.

- Pcdata U.S.

- RightHand Robotics

- GreyOrange

- Motion Controls Robotics

- SCHUNK GmbH & Co. KG

- Boston Dynamics

- HandHeld USA

- Taylor-Dunn, a Plaris Industries business

- Softeon

- The Raymond Corp.

- Omnia by Rotacaster

- Rufus Labs

- Waypoint Robotics

- Barcoding, Inc.

- Productive Robotics Inc.

- KEITH Manufacturing Co.

- HighJump

- Green Cubes Technology Corp.

- enVista Corp.

- Delta-Q Technologies

- Generix Group

- Trelleborg Wheel Systems

END-OF-LINE PACKAGING EQUIPMENT

Signode Industrial Group, Glenview, Ill., displayed a wide variety of its customer-focused innovations.

Among those developments on display was the Octopus Compact 20 TSI automatic rotary ring stretch wrapper. With a compact size and intuitive operation, the Octopus Compact 20 TSI is ideal for manufacturers looking to increase productivity without compromising space.

The newly released Signode BXT3 series is the next generation of battery-powered combination tools for plastic strapping, designed to help enhance safety, convenience and ease of use. The tool’s variable tension speed gives operators complete control of the speed applied to the strap. The series features real-time indication of tension force that increases the reliability of the process and reduces operating errors.

Also, the Storfast product portfolio consists of high-density automated storage and retrieval systems (AS/RS) that can be expanded as capacity requirements change.

Signode Industrial Group, LLC

847-724-6100

www.signodegroup.com

PORTABLE, RUGGED IT SOLUTIONS FOR MANUFACTURING, SUPPLY CHAIN OPERATIONS

JLT Mobile Computers, Tempe, Ariz., presented its end-to-end rugged mobile IT solutions for the manufacturing and supply chain industry.

The new JLT RepairEngine online maintenance management tool now includes third-party products from most manufacturers. The easy-to-use JLT RepairEngine web tool gives users the ability to start and track repairs 24/7, and provides insight into the health and status of the hardware deployment.

Also new to the U.S. market are the 5-inch MH1005A rugged handheld, the 7-inch MT1007A rugged tablet and the 10.1-inch MT2010A rugged tablet. All products are IP65-dustproof and water-resistant, capable of operating in temperatures of 14-122°F, built to withstand even the most challenging working environments and tested to MIL-STD-810G requirements.

Lastly, JLT partnered with StayLinked, Irvine, Calif., to develop the StayLinked SmartTE operating system, which transforms traditional terminal emulation screens into graphical, touch-based screens. The unique architecture of StayLinkedTE connects mobile devices to host-based applications such as warehouse management systems (WMS) and enterprise resource planning (ERP) systems in a high-performance manner. StayLinked SmartTE also allows workers to utilize the entire screen without sacrificing usability for the sake of screen space. Customers retain all application functionality, and can seamlessly migrate to modern operating system,s including Android and Windows 10 and new state-of-the-art computers without having to touch the host application.

JLT Mobile Computers, Inc.

844-705-4200

www.jltmobile.com

LIFT SOLUTIONS

Wildeck, Inc., Waukesha, Wis., announced a line of RiderLifts, which are equipped with two synchronized direct-acting hydraulic cylinders, and offers a capacity of 5,000 pounds and carriage sizes up to 102 square feet. Available in three different capacity sizes (XL, 2XL and 4XL), RiderLifts comply with ASME A17.1/CSA B44 “Safety Code for Elevators and Escalators, allow authorized personnel to safely travel between levels with their materials and are constructed with heavy-duty welded structural components, making it the ideal solution for industrial applications such as mezzanine platforms, rack systems and pick modules.

Also on display was the XpressLift VRC, specifically designed to efficiently integrate vertical lifting into automated conveyor systems. Designed and manufactured to meet ANSI/ASME – B20.1 “Safety Standards for Conveyors,” the XpressLift VRC can quickly transfer totes or cartons of materials typically weighing up to 75 pounds at speeds up to 350 feet per minute. Plus, the XpressLift VRC design is a closed-loop AC vector drive mounted at the top of the lift. Meanwhile, an encoder continuously monitors the motor and controls the braking system for safety, allowing for ultra-smooth, high-speed lift operation. Carriage stopping is also performed by the AC vector drive, extending the life of the mechanical motor brake.

Wildeck’s NetGate Pick Module Safety Gate and Pallet Drop Zone (DZ) Safety Gate are designed to provide personnel with enhanced levels of protection while accessing large pallet loads at elevated levels. In both instances, as one side of the gate is lifted, the other closes, ensuring that the elevated ledge is always protected.

Wildeck, Inc.

262-249-4000

www.wildeck.com

END RIDER PALLET TRUCK

The new Yale MPE060-080VH end rider pallet truck series from Yale Materials Handling Corp., Greenville, N.C., features a comprehensive lineup of ergonomic, productivity enhancing and maintenance-friendly features. The optional extended platform is said to provide over 30% more usable foot space, and the Ultra Cushion helps reduce shock and vibration. Plus, the Precision Pick feature enables precise bi-directional control of speed and coast functions at the press of a button. The end rider is designed with extended service intervals of up to 1,000 hours. LED platform and fork lights help increase operator awareness in low light or congested areas, like dim storage aisles and dark trailers. The end rider’s Smart Shift bundle offers shortcuts to improve operator efficiency. For example, operators can raise and lower forks with a single touch, and use the cruise control system to relax over long hauls. The Smart Acceleration feature automatically selects two distinct acceleration profiles based on application, load and task, while Yale Smart Slow Down automatically reduces speed in cornering for improved stability.

Through its partnership with Yale, Balyo, Boston, showcased its mobile robotics technology, including the Driven by Balyo software navigation technology, which outfits standard forklift trucks with a LIDAR scanner and proprietary software to enable robots to self-locate by recognizing existing building features, like walls, racks, columns, machines and more. The robot constantly performs a 360-degree scan of its environment, correlating what it sees in real time with the reference map created during onboarding. A proprietary processor acts as the robot’s “brain,” connected to mechanical components and commanding all normal functions, including forward, reverse, stop, turn, lift, lower and more.

Yale also debuted the new robotic reach truck, what is said to be an industry-first dual-mode pantograph robotic lift truck capable of autonomously depositing and retrieving loads from locations as high as 30 feet and reaching into double-deep storage. The high-lifting capability of the reach truck makes it an ideal fit for distribution centers facing a shrinking labor pool and pressure to maximize vertical storage space to accommodate inventory growth driven by e-commerce. The JBT-intelligent robotic reach truck uses a combination of sensors and 3D cameras for maximum precision and effectiveness at higher-level storage locations, capable of exceeding the productivity of operator-driven trucks.

Yale also showcased the company’s first counterbalanced lift truck with a factory-integrated lithium-ion battery pack. Designing the Yale ERPVL around a space-saving lithium-ion battery pack reduces truck weight, enabling better acceleration and reduced energy consumption. The smaller size of the lithium-ion battery opens space under the seat for improved access and convenience while entering the truck and driving.

And, the concept vehicle’s next-generation chassis is compatible with any motive power source, including hydrogen fuel cells, lithium-ion batteries, internal combustion engines and more. This flexibility offers customers the power source of their choice while standardizing designs to ease adoption. The chassis also provides key ergonomic advantages, such as visibility, comfort and easy access.

Also on display were:

- Power Suite, a broad range of power options, including hydrogen fuel cells, lithium-ion batteries, internal combustion engines and lead-acid batteries.

- Robotic lift trucks. Yale lift trucks are outfitted with robotic technology to operate as self-guided vehicles, autonomously moving loads from both floor-level and elevated locations with no extra infrastructure like tape, wire or magnets.

- Yale Vision. Monitor virtually any mobile warehouse equipment and use telemetry data for automated alerts, real-time analytics and actionable insights, all accessible via online dashboards and what is said to the industry's first telemetry mobile app.

- Lift truck simulators. Yale's virtual reality training tools simulate the operation of several lift truck models, even matching specific customer environments to help build operator confidence, expedite learning and limit risk of damage to trucks.

Yale Materials Handling Corp.

252-830-0261

www.yale.com

ROBOTIC SINGULATOR

Material Handling Systems, Louisville, Ky., combines advanced computer vision, controls, gripping technology and a 5-axis delta robot to automate the task of singulating items in preparation for sorter induction.

Ideal for parcel processing operations handling bulk quantities of smaller-size packages, this robot uses proprietary vision software and algorithms to pick individual items from bulk flow, then properly orients them and places them in a single-file stream for downstream processes.

The solution uses a vacuum-based end effector with a variety of suction cups to handle packaging types commonly found in e-commerce and parcel processing environments, from rigid corrugate cases to malleable polybags.

Material Handling Systems, Inc.

502-636-0690

www.mhsinc.net

ETHER SOLUTIONS & CONTROLLERS

Beckhoff Automation, Savage, Minn., showcased multiple new technologies designed for material handling and logistics operations.

On display was the EK1000 EtherCAT TSN Coupler and EtherCAT G offerings, which assist distribution centers in the implementation of real-time systems.

Beckhoff also announced EtherCAT G and EtherCAT G10, which provide communication at 1 Gbit/s and 10 Gbit/s, respectively, in conformance with the IEEE 802.3 Ethernet standard.

The new Beckhoff CX7000 embedded controller presents a compact EtherCAT controller, boasting a single-core, 400 MHz ARM Cortex-M7 processor. The DIN rail-mountable controller maintains minimum footprint, and directly connects to the full range of Beckhoff EtherCAT I/O modules via a backplane.

The C6015 Industrial PC (IPC) with an Intel Atom processor and the C6030 IPC available with Intel Core i-series processors are ideal for mid-range to complex machine control as well as edge computing and IoT gateway devices to connect existing systems to major cloud platforms.

Also on display were TwinCAT Analytics and HTML5-enabled TwinCAT HMI software for industrial displays and mobile devices, and the AMP8000 distributed servo drive system with One Cable Automation, which minimizes machine and equipment footprint.

Beckhoff Automation LLC

952-890-0000

www.beckhoffautomation.com

VERTICAL LIFT MODULES

Kardex Remstar, Westbrook, Maine, displayed the new LR 35 Vertical Buffer Module and the Shuttle XP Vertical Lift Module (VLM).

The LR 35 goods-to-person, bin handling solution is ideal for any operation involved in handling single-part or small-volume orders. The unit consists of a shelf system with automatic bin handling, picking stations and their own logistics software. The LR 35 delivers totes of discrete items directly to the operator with minimal wait time.

Meanwhile, the Shuttle XP is integrated with pick-to-light technology and Power Pick Global inventory management software. By utilizing the vertical space from floor to ceiling, vertical storage systems recover up to 85% floor space.

Lastly, Kardex Remstar demonstrated the new Remote Support platform, including Remote Assistance, which manages remote diagnostics, allowing for simple maintenance requests to be performed remotely instead of onsite reducing downtime; and Remote Analytics, which gives users access to machine data anywhere via a web browser.

Kardex Remstar, LLC

800-639-5805

www.kardexremstar.com

GOODS-TO-PERSON SOLUTIONS

Bastian Solutions, Indianapolis, Ind., showcased the AutoStore Black Line and Red Line storage systems that allow complete configurability and flexibility. Bins are stacked vertically in a grid and retrieved by robots that travel on the top layer of the system. This makes it possible for the grid to be placed around columns, on mezzanines and on multiple levels. AutoStore Red Line is said to pioneer cube-based automation to revolutionize warehousing with a simple and flexible solution. AutoStore Black Line introduced a new robot, relay port and taller bin design to deliver 650 bins per hour and 99% system uptime.

The goods-to-robot picking robotics integrates 2-D and 3-D vision components with a flexible and robust end-of-arm tool (EoAT).

Meanwhile, the robotic print and paperwork inserter accurately places the proper paperwork in the proper carton, every time. How it works is, a carton enters the robotic cell, and is then scanned for LPN identification. The proper paperwork is then retrieved and sent directly to the line-side printer. While exiting the printer, the paperwork is scanned for a confirmation match, and then robotically picked and placed into the carton. A verification scanner is located within the robotic place zone for final match confirmation. Features include paperwork insertion rates of 25 cartons per minute, robotic cell configuration that incorporates up to 3 printers for back-up redundancy and meets OSHA, RIA and ANSI specifications. And, it can be used to place various paperwork, including invoices, return information, picking lists, packing slips, promotional media and operator work instructions.

The ZiPline shoe sorter is capable of throughput rates reaching 18,000 cases per hour and speeds up to 650 feet per minute. This all-electric divert is ideal for high-volume sortation of varying sized products, and features a patent-pending “gentle touch” divert system for positive and gentle sortation.

Bastian Solutions’ Bluehound Asset Tracker is an Internet of Things device that tracks the status and travel path of assets. With sensor-enabled technology, BlueHound trackers communicate through GPS, cellular connection and Bluetooth technology, allowing users to view the status and location of assets with real-time reporting on any device.

Lastly, the Rogue composite pallet combines the benefits of the wood block pallet (strength) and plastic (cleanliness, international shipping and re-usability). Rogue is constructed with low environmental impact materials, is rackable up to 2,800 pounds, is impact resistant and ideal for defined loop supply chains such as grocery, distribution centers and more.

Bastian Solutions

888-575-9992

www.bastiansolutions.com

APP-BASED SOLUTIONS FOR FORKLIFT FLEET MANAGEMENT

ELOKON, Atlanta, reimagined its ELOfleet forklift fleet management system as an app-based solution that can be installed on virtually any Android device to control forklift access, perform safety checklists, monitor vehicle impacts and manage forklift fleet data. The ELOfleet solution enables drivers to log in into lift trucks via the Android device’s RFID reader, complete checklists on the Android device and report reliable impact data in real-time. The web-based dashboard with drill-down reporting analyzes a wide range of lift truck data with key performance indicators (KPIs). ELOfleet is OEM-independent, and is ideal for mixed fleets.

Also on display was the ELOshield forklift accident-avoidance system. Using UWB sensor technology and adjustable object-detection zones, ELOshield helps prevent forklift-pedestrian and forklift-forklift collisions.

The new Smart Safety Vest works with ELOshield proximity detection system to alert both the pedestrian and the forklift driver if they get too close. As a failsafe, the system sends multiple warnings—by sight (long-range LED lights), sound (acoustic alarm) and feel (vibration alarm). This wearable health and safety vest slips on like an ordinary vest, and when not in use, automatically recharges on an inductive charging stand.

Meanwhile, ELOprotectPRO is a laser-based, collision-avoidance system designed specifically for very narrow aisle lift trucks. The new version of extends its object-detection range to approximately 30 feet, and allows more than one lift truck to operate in the same aisle at the same time.

ELOKON also announced the opening of its new U.S. subsidiary in Atlanta.

ELOKON, Inc.

678-293-4089

www.elokon.com

AUTOMATED WAREHOUSING ROBOTIC SOLUTIONS

Geek+, China, demonstrated its M100 moving system, Geek Robot Shuttle System C200 Series and automated forklift.

These automated and intelligent devices are equipped with cutting-edge technologies, robotics and AI and are capable of handling the material (bin-carrying/pallets/boxes/single pieces) from goods receipt and unloading and storage to picking, packing and order shipment.

Geek Moving System features simple deployment, elegant industrial design, high-precise navigation and long-lasting battery life, making it compatible with cage trolley traction, conveyor roller, lifting and human-machine interaction.

The Geek Robot Shuttle System C200 Series is an innovative tool to do bin-carrying for picking, carrying standard bin to workstation for picking with intelligent scheduling, accurate navigation and automatic charging. Suitable for multi-SKU storage and picking application, this shuttle system is designed to operate on single layer rack and multi-layer mezzanine racks, fits with existing warehouses and adapts to change of work load by adding and removing robots.

The automated forklift self-drives through SLAM navigation, and is capable of automated storage and retrieval. Sensors detect the measurement and position of the goods on the shelves, pinpoint the pallet slots and carry the goods to the appointed area under the instruction from the scheduling system.

Geek+ Robotics

+852) 3462 2128

www.geekplusrobotics.com

AUTONOMOUS PALLET HANDLING

Vecna Robotics, Cambridge, Mass., unveiled its fifth generation autonomous pallet handling. Vecna's new Pallet Jack is said to be the first self-driving vehicle to include autonomous pallet identification, lifting and pickup, as well as an OEM agnostic base.

The enhanced software delivers faster, smoother pickups across a broader variety of pallets and goods, including pallets with bottom boards and partial pallets. This new technology is a further extension of Vecna's Autonomy Stack, which features dynamic obstacle avoidance, topological reasoning, local decision making, high-confidence navigation and self-learning capabilities. The Autonomy Stack enables Vecna vehicles to learn new skills as they work through diverse levels of demands, seasonal needs and market changes.

Also on display was Pivot.al, what is said to be the world's first AI-driven orchestration engine. Pivot.al coordinates workflows and tasks in real-time based on the capabilities, location and availability of both humans and robots in operation. Pivot.al also reallocates human and vehicle assignments based on the level of demand and shares information across people, robots and associated systems.

Vecna Robotics

617-444-9263

www.vecnarobotics.com

BATTERY SYSTEMS

Storage Battery Systems, LLC, Menomonee Falls, Wis., partnered with Systems Sunlight S.A., Greece, to develop two new battery technologies.

Copper Stretch Metal (CSM) motive power batteries offer longer run-time under extreme conditions. The higher energy content of CSM technology and reduced internal resistance contribute to increased operating time of material handling trucks.

Meanwhile, the SUNLIGHT LiON FORCE is said to feature one of the most innovative lithium-ion solutions for motive power applications in the world based on unparalleled connectivity and serviceability. With 17 layers of safety, it dubbed one of the safest and most efficient lithium-ion battery solutions in the marketplace.

Storage Battery Systems LLC

800-554-2243

www.sbsbattery.com

CLOSED TUBE ROLL-FORM PALLET RACK SYSTEM

Steel King Industries, Inc., Stevens Point, Wis., highlighted its SK2000 closed tube roll-form rack systems, ideal for a wide range of warehouse applications and markets, including food and beverage, retail, agriculture and more.

Featuring a fully welded tubular upright, the SK2000 racks offer superior impact resistance over open-back style uprights.

Its columns boast a unique 90-degree bend and no corner holes. Plus, this boltless rack system with teardrop connections and auto-engaging safety locks can be assembled without tools. Columns are available in multiple sizes and thicknesses, according to application needs.

Steel King Industries, Inc.

800-826-0203

www.steelking.com

PALLET SYSTEM CONVEYORS

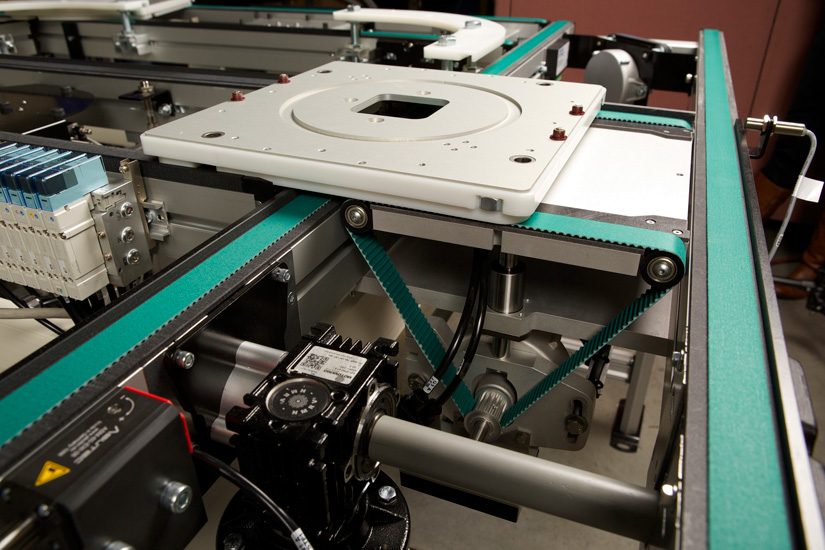

Dorner, Hartland, Wis., exhibited its 2200 Precision Move Pallet System conveyor, designed to provide accurate positioning and routing of parts for assembly, robotic and inspection applications. New features include heavy load corners, tight turn corners, low-profile lift and locates, elevators and more. Plus, easy programming, fast setup and flexible deployment make the 2200 Series ideal for systems that need an infeed and discharge to a universal robot.

Also on display is the SmartFlex Pallet System conveyor, which is engineered for product routing, control and inspection in small- to medium-size assembly automation applications. SmartFlex components include merge and divert modules, lift and locate stations, cushioned pallet stops and a unique pin tracking system to guide pallets through 90-degree turns.

Dorner also demonstrated the capabilities of its 3200 Series Conveyor with Intralox Activated Roller Belt (ARB) Technology, which uses low- and high-friction angled rollers within the belt to help smoothly guide and align items of all sizes in merging, diverting and aligning applications, and FlexMove conveyors, a flexible chain conveyor system for the assembly automation and packaging industries.

Dorner Mfg. Corp.

800-397-8664

www.dornerconveyors.com

SORTATION & DISTRIBUTION TECHNOLOGY

BEUMER Group, Somerset, N.J., displayed its latest sortation and distribution technology, including:

- A working sorter control room area showing how the BEUMER sorter is managed and operated from inside a distribution center, with a focus on Big Data and Internet of Things.

- An immersive virtual warehouse experience.

- An interactive touch-screen area showing all phases of a distribution and parcel center featuring new BEUMER technology.

- A palletizing and packaging area displaying stretch-hooded pallets and focusing on relevant sortation and distribution technology.

BEUMER Group

732-893-2800

www.beumergroup.com

BATTERIES, CHARGERS & BATTERY MONITORING DEVICES

Douglas Battery, Reading, Pa., showcased its full offering of batteries and chargers.

On display were the Legacy High Performance battery, Legacy Low Maintenance battery and Legacy Arctic battery, which include positive lead plates that deliver excellent conductivity, high corrosion-resistance and optional quick connect cables to speed cable replacement.

LegaC modular chargers, the company’s state-of-the-art line of battery chargers, are suitable for a wide range of battery capacities and are designed to maintain peak efficiency at all times.

Engineered with the latest digital power control technology, Raptor Rapid chargers enable batteries designed for fast charging to be safely charged anytime during the shift day, thus avoiding having to swap batteries during 2- to 3-shift operations.

The Douglas DataTrac battery monitoring device is installed onto the battery to capture real-time information on a range of battery parameters. This small unit records minute-by-minute data that is automatically uploaded to a PC or tablet via Bluetooth. The Douglas DataTrac Reporting Suite then analyzes and converts the data into easy-to-read reports with actionable information.

Douglas Battery

800-211-3684

www.douglasbattery.com

HIGH-VOLUME, LOW-SPEED CEILING FAN

Patterson Fan Co., Blythewood, S.C., redesigned the High-5 high-volume, low-speed ceiling fan to sport a new 43-inch frame (10 inches shorter than the previous version), making it better suited for buildings with lower ceiling heights.

Ideal for industrial facilities such as warehouses and manufacturing plants, it now includes an updated clamping mechanism that is placed over the beam to adjust the bolts.

The High-5 generates a breeze during the warmer months, producing a 6-8° cooling effect, and promotes de-stratification through the colder months.

Additional features include five blades for maximum air movement, custom ground helical-cut gears for quiet and durable operation, double lip seals that prevent any potential oil leakage and premium grade lubricant designed for gears operating under severe temperature and load conditions.

Patterson Fan Co.

800-768-3985

www.pattersonfan.com

VISION SOLUTIONS

Teledyne DALSA, and Teledyne e2v, Canada, exhibited their industrial vision solutions targeted at logistics, robotics and packaging applications.

BOA Spot XL. Preview this new all-in-one vision sensor with integrated lighting, lens cover and easy-to-use software designed for error proofing, identification, general inspection and robot guidance.

Genie Nano 5GigE. What is said to be the industry’s first 5 Gigabit, GigE Vision area camera is ideal for machine vision inspection.

Linea ML. Preview this CMOS line scan camera with visible and near infrared spectrum capabilities. Equipped with multiple spectral bands, this camera is ideal for print inspection and recycle sorting

Snappy 2M. This CMOS image sensor integrates real-time features ideal for fast and accurate scanning of 1D and 2D barcodes and other applications, including embedded imaging, virtual reality and intelligent surveillance cameras.

Z-Trak 3D laser profiler. Z-Trak covers measurement ranges from 10-1,000 mm, and delivers highly linear results by combining reflectance-based dynamic laser power control and an optimized optical path.

Teledyne DALSA

978-670-2000

www.teledynedalsa.com

MOBILE SORTATION SYSTEM

6 River Systems (6RS), Waltham, Mass., announced Mobile Sort, a new solution that enables warehouse operators to intelligently generate and fulfill batched orders using 6RS’ robots, mobile sort stations and cloud-based software enhanced with machine learning.

Mobile Sort stations consist of smart kiosks, mobile put-to-light walls with validation sensors that work with 6RS’ cloud-based software and 6RS collaborative robots called “Chucks.” 6RS’ intelligent allocation engine continuously generates highly optimized batches of work that group orders into the most efficient picking jobs. Chucks delivers empty totes to associates in active picking areas and directs associates to complete picks. Totes are then delivered to take-off points, where they are sorted into orders using the Mobile Sort stations.

6 River Systems

866-602-4825

https://6river.com

MODULAR PALLET RACK SAFETY NETTING

Adrian’s Safety Solutions, Knoxville, Tenn., launched new Modular Pallet Rack Safety Netting, designed for walkway and work area product fall protection.

The modular design allows for overlapping or tiling, so any space can be easily protected right out of the box.

Modular Safety Netting keeps loose items or cartons from falling into a work space or aisleway.

Adrian’s Safety Solutions

866-423-3638

www.adrianssafetysolutions.com

AUTOMATED WAREHOUSE MANAGEMENT SOLUTIONS

Numina Group, Woodridge, Ill., demonstrated a host of automation technologies, including:

Real time Distribution System (RDS) is said to be the industry’s most complete and scalable warehouse execution and control system (WES-WCS). RDS is a modular, high-performance software that controls and manages a wide array of automation technologies to streamline the entire pick, pack and ship order fulfillment operation.

RDS Pick by Voice technology is speaker independent, requires zero voice training and combines voice commands/responses and hands-free camera-based barcode scanning. The voice picking application supports pick to carton, batch carts, fork trucks and conveyor picking. RDS also includes optimized order release and cartonization logic.

Auto Print Fold Insert (PFI) prints, folds and auto inserts from 1-7 8.5x11-inch packing sheets into multiple height and carton sizes. PFI automates out the bottleneck of manual order documentation with insertion of packing sheets, return labels, promotional materials, coupons and other requirements as needed. PFI technology can scale from 10-50 or more CPM operations to reduce 30 or more seconds of labor from every shipment.

One Step Plus Print and Apply labeling auto applies a combination full 8.5x11-inch packing sheet and shipping label to full case or re-packed mixed SKU cartons to reduce 30-45 seconds of labor per parcel shipment. The system is ideally suited for high-volume e-commerce and B2B order fulfillment applications.

X-Press PAL Print and Apply Labeling auto applies one or more 4x6-inch pack slips under a removable 6x8-inch shipping label. X-Press PAL automation includes inline scan, weigh, dimension with automatic application of packing slips, compliance, carton content and shipping labels.

Put to Light Order Consolidation technology essentially sorts by lights and allows parallel batch order picking across multiple pick zones. At the order consolidation area, operators scan and put the batch picked SKUs to order consolidation shelf positions at a rate of 400-500 items per hour.

RDS Pick by Voice combined with Put to Light order consolidation provides the ability to batch pick hundreds of orders in a highly accurate manner across all warehouse zones. Order totes or hamper carts are directed to the Put Walls for order consolidation and pack to shipping cartons. Batch cart picking is ideally suited to the latest generation of autonomous vehicles that automate the transport of the batch pick cart to the put walls, packing and shipping areas.

The Numina Group

630-343-2600

https://numinagroup.com

FAN OFFERS INIFINITE NUMBER OF SPEEDS & MOUNTING OPTIONS

Big Ass Fans, Lexington, Ky., introduced Pivot 2.0, which offers virtually infinite number of speeds and versatile mounting options.

The fan’s durable steel cage keeps workers safe. Plus, it cools air up to 120 feet thanks to a 6-foot diameter motor.

It boasts versatile installation with ceiling, beam and column mounting options, and produces air in the right spot with 73 airflow positions and variable speed controls.

Big Ass Fans

877-244-3267

www.bigassfans.com

MOBILE COMPUTERS FOR ON-DEMAND ECONOMIES

Zebra Technologies Corp., Vernon Hills, Ill., announced the ultra-rugged Android-based MC9300 mobile computer, TC8300 touch computer and ATR7000 RTLS reader.

Designed for warehouses, manufacturing and logistics operations and back-of-store retail environments, the MC9300 is ideal for inventory management, receiving/put-away, returns processing, cross docking, quality control, parts tracking and price audit applications. Its advanced scanning technology can read direct part marks (DPM), dot peen and laser-etched barcodes, and quickly capture 1D or 2D barcodes in virtually any condition and from 3 inches to as far as 70 feet. In addition, the MC9300’s PowerPrecision+ 7000mAh battery maximizes worker efficiency and productivity. Additionally, it is also virtually water-, drop-, dust- and tumble-proof, and features a system of heaters and a freezer-rated battery for frost-free operations and cold storage environments.

The TC8000 is optimized for picking and new augmented reality (AR)-based applications. It uses the same Qualcomm chipset as the MC9300 for an extended lifecycle, and is available with the Mobility DNA software suite and LifeGuard for Android support as well as DPM capabilities. Designed for asset tracking applications in warehouses, manufacturing plants and other large indoor facilities, the new ATR7000 RTLS reader identifies and analyzes the coordinates of all passive RFID tags in its coverage area, providing real-time visibility into the pinpoint location of all tagged assets. With the ATR7000, businesses can see where inventory, forklifts, equipment and even workers are located, if they are on the move and in which direction they are moving, helping improve workforce productivity and operational efficiency.

Zebra Technologies Corp.

866-230-9494

www.zebra.com

IOT-ENABLED WEARABLE GLOVE

ProGlove, Chicago, debuted MARK 2 wearable technology that provides hands-free scanning solutions across a number of industries.

MARK 2 can connect to a corporate network via Bluetooth Low Energy (BLE) or 868 MHz radio frequency. It enables the user to scan up to 5 feet away from a device, and includes a battery that holds up to a 15-hour charge. Instant Worker Feedback provides information to employees, reporting errors or pointing out prioritized shipments.

ProGlove

833-357-2273

www.proglove.com

TASK SUPPORT VEHICLE FOR E-COMMERCE FULFILLMENT CENTERS

Big Joe, Lombard, Ill., introduced a new version of its Joey series of vehicles developed for high-volume e-commerce fulfillment centers.

The Joey J1HD Task Support Vehicle features a maximum operator platform height of 210 inches with improved mast and travel speeds at ground level.

The J1HD includes a 48-volt control system and large lithium battery, more carrying capacity and volume, increased towing capacity, LED drive lights and forward-facing blue lights.

Big Lift, LLC

630-916-2600

www.bigjoeforklifts.com

INDUSTRY 4.0-ENABLED SOLUTIONS

SICK, Minneapolis, launched Lector621, a compact image-based code reader for reliable detection of 1D, 2D, stacked codes and plain text. The high-performance DPM decoder can read laser or dot-peened codes perfectly, even in the case of low contrast levels, contamination or poor code quality. Other features include optimal reading performance with intelligent decoding algorithms to ensure high throughput, stable reading even in changing light conditions with variable illumination concept, easy integration due to compact design and swivel connector and Simple assembly as an integrated unit with lensing and lighting built in.

SICK also presented its Logistics Gets Smart solution, which entails programmable and self-learning cameras, reliable safety sensors for human-robot collaboration, reliable track-and-trace systems on conveyor, and state-of-the-art package analytics software to monitor performance. All these devices are connected with one another via the cloud, implementing Industry 4.0 along the entire value-creation process.

SICK also launched nanoScan3, a new ultra-compact safety laser scanner that combines smart safety functions with excellent measurement data quality for accurate and reliable localization. With an overall height of just 8 centimeters, this space-saving sensor can be used wherever machines and vehicles require maximum performance, but have minimal mounting space. Based on microScan3 technology, the 2D safety sensor is programmable, measures data output for navigation support and opens up potential applications where space is extremely critical such as mobile intralogistics, mobile assistance and service robotics with autonomous transport platforms and carts, as well as collaborative robots (cobots).

outdoorScan3 is a safety laser scanner that allows AGVs to navigate safely through outdoor industrial environments. Thanks to its outdoor-safeHDDM scanning technology, outdoorScan3 works safely and reliably in all weather – sun, rain, snow or fog. Plus, the intelligent software algorithm of the outdoorScan3 detects rain and snow, easily filtering out these environmental influences.

And, the TDC-E Telematic Data Collector is used to collect, analyze, store and transmit sensor data in mobile and stationary applications. This new solution offers extended functionalities for capturing, processing and transmitting process and sensor data. As a physical device, the TDC-E acts as the connection point between controllers, sensors and intelligent devices and the cloud. Once real-time performance data is collected (e.g., levels, drive temperatures, protective field infringements, reading rates, uptimes or collisions), the information is summarized and analyzed in the TDC-E to minimize the data volume that is forwarded to external applications or to the cloud. The new TDC-E is also used as a reliable, adaptable security and management tool for the sensor-supported management and monitoring of production lines, mobile machines, plants split over several locations, wind farms and similar facilities.

SICK Inc.

952-941-6780

www.sickusa.com

AUTOMATED ORDER PICKING SYSTEMS

Cimcorp, Norcross, Ga., exhibited its line of turnkey robotic order fulfillment and tire handling solutions, designed to ensure product freshness in food distribution and to optimize warehouse operations during seasonal peaks.

Cimcorp’s robotic solutions can fully automate distribution or work as an “island of automation” amongst other manual processes. For distribution centers with perishable goods—such as in the fresh produce, bakery and dairy industries—Cimcorp offers buffer storage and order picking as a single operation. This enables such facilities to shorten lead times, thereby maximizing product shelf life.

Cimcorp’s solutions also address shifting consumer demands for more frequent orders and smaller order lines, as well as seasonal spikes in volume. That’s why all material flow is managed by Cimcorp’s warehouse control system (WCS), which also provides full product tracking and traceability.

Cimcorp USA, Inc.

888-797-3703

www.cimcorp.com

SHOE SORTER

VanRiet Material Handling Systems, The Netherlands, presented its improved HC Sorter, a sliding shoe sorter optimized to U.S. specifications.

Improvements are the single-sided shoes and the electric divert switch. What is dubbed to be the fastest closed-deck shoe sorter on the market, the HC Sorter features a closed deck to ensure no dirt or pieces of cardboard get stuck inside the sorter. The deck also results in low noise and promotes safe working conditions for warehouse staff.

The smooth sorting process allows the sorter to handle fragile products at a speed up to 3 meters per second. The HC Sorter can also sort very small and thin products, as well as large packages weighing up to 50 kilograms.

VanRiet Material Handling Systems

+31 (0)88 60 68 111

www.vanrietgroup.com

AS/RS TOTE BOXES, PLASTIC PALLETS, DIVIDER SYSTEMS

Flexcon Container, Berkeley Heights, N.J., exhibited its new Universal and AS/RS Tote Boxes, Divider Systems and Pallets.

The Totes and Divider Systems can handle, store and protect an infinite range of products in any automated, semi-automatic or manual system with maximum space efficiency.

Meanwhile, the newest AS/RS totes are compatible with virtually any robotic system, and feature unique reinforced bottoms that resist deflection under heavy loads.

Other new products include “X-Corr” triple-strength totes and pallet-sleeve systems and a new line of molded plastic pallets.

Flexcon Container

908-871-7000

www.flexcontainer.com

WEARABLE BARCODE, RFID DEVICE

FEIG ELECTRONICS, Duluth, Ga., introduced HyWEAR Compact, the new hybrid barcode and RFID Wearable that makes logistical processes more efficient and hands-free for warehousing, distribution, manufacturing, parcel delivery and logistics operations.

The HyWEAR Compact is said to be the first wearable device of its kind, supporting both barcode and RFID technology in a wearable format.

The small electronic reads 1D and 2D barcodes, RAIN RFID transponders or both barcode and RFID, and attaches to a fingerless glove, leaving the user’s fingers and arms free to move.

This lightweight device ergonomically and comfortably rests on the back of the hand, providing unrestricted freedom of movement for the user.

Additional features include WLAN roaming, which allows the HyWEAR Compact to automatically switch from one radio cell to the next without interruption. The device transparently connects to the new WLAN access node as it moves within range of stronger nodes, seamlessly integrating into existing process chains.

The HyWEAR Compact also boasts a high-capacity, long-life, rechargeable battery that can power the device for the duration of a working shift.

FEIG ELECTRONICS

770-491-8060

www.feig-electronics.com

ROBOTIC CONVEYOR & TRANSPORT SOLUTION

IAM Robotics, Sewickley, Pa., introduced the most recent advancements to the Swift Solution, which features a new robot design complete with conveyor integration and a transport robot that works in conjunction with Swift to exchange full or empty totes.

The redesign includes a smoother lift and is available with a fixed tote or integrated motorized drive roller (MDR) for automatic tote transfer. The adjustable carriage can match the height of a facility’s existing conveyor infrastructure for simpler integration.

The company also introduced Bolt, a new transport robot designed to further improve throughput of the Swift solution by exchanging totes with Swift, and delivering the full tote to the next process in the fulfillment cycle such as packing and shipping.

IAM Robotics

412-626-7425

www.iamrobotics.com

AUTOMATED SORTATION SYSTEM

Solution Net Systems, Quakertown, Pa., expanded its automated sortation portfolio with the SNS Modular Sortation System, which provides sortation solutions for a wide range of materials, including polybags, padded envelops and small and large parcels.

Ideal for order and inventory accuracy, reverse logistics, receiving, shipping, order fulfilment and pick-and-pack applications, this quiet, scalable solution can handle multiple divert points on a single belt while utilizing 24-volt motor driven rollers.

Its all-electric design eliminates the reliance on inefficient pneumatic solutions.

And, a safe divert mechanism delivers high performance without exposing personnel to large mechanical pushers.

With the use of the company’s enterprise FAST software, this comprehensive portable and modular sortation solution can quickly integrate into an existing system and easily expand to streamline workflow, aid in product visibility and optimize production efficiency.

Solution Net Systems

877-619-6763

https://solutionnetsystems.com

CONSULTING FIRM DISCUSSES E-COMMERCE DISTRIBUTION, HOW TO SCALE DISTRIBUTION

Commonwealth Supply Chain Advisors, a Boston, Mass.-based international consulting firm, discussed topics such as e-commerce distribution and how to scale distribution in its presentations.

The company also shared insights on the latest innovations and advances in processes and technologies in supply chain and distribution.

Commonwealth Supply Chain Advisors

617-948-2153

www.commonwealth-sca.com

MOBILE ROBOTIC PALLET STACKER

AutoGuide Mobile Robots, Chelmsford, Mass., expanded its Max N10 Modular Mobile Robot platform with the launch of a new counterbalanced pallet stacker configuration.

The on-site demonstration featured the new Max N10 Pallet Stacker picking and placing pallets between the floor level and the bed of an industrial cart attached to an AutoGuide Max N10 Tugger. With its smart pallet finding capability, the Max N10 Pallet Stacker recognizes the pallet shape within an expected window, determines its location and orientation and then dynamically re-plans its travel path for a successful pick. This enables the pallet stacker to both reliably pick pallets from the bed of the tugger pulled cart and pick a displaced or misaligned pallet from a floor location. Both Max N10 Mobile robots are navigating using the natural features available within the show floor—no tape, RFID tags, magnets or beacons required.

The pallet stacker utilizes a patent-pending, application-specific, pallet handling attachment in combination with the purpose-built, industrial-base vehicle. Previously fielded Max N10 configurations include Tugger with trailers, conveyor deck and car mover units for distribution centers and industrial manufacturing facilities.

AutoGuide Mobile Robots

502-542-6436

www.agmobilerobots.com

PORTABLE THERMAL BARCODE PRINTER

Toshiba America Business Solutions, Lake Forest, Calif., spotlighted its lineup of ruggedized, portable and industrial thermal barcode printers.

Toshiba's high-speed industrial B-EX6 printers deliver up to 6-inch labels for virtually any labeling application. The printers’ unique Ribbon Save technology minimizes ribbon consumption and reduces waste, while a large-capacity ribbon (up to 800 meters) lessens the need for frequent media replacement.

Toshiba America Business Solutions, Inc.

949-462-6000

http://business.toshiba.com

ONLINE SOFTWARE FOR LOADING DOCK ANALYTICS

Systems LLC, Germantown, Wis., released the new iDock Connect, an online software for loading dock analytics.

Facilities can log in to their online account at iDockConnect.com from any device with internet connectivity. From there, they can view visual reports with current dock activity, review efficiencies of loading/unloading and compare operation analytics of docks between two different time periods.

iDock Connect can also be set up to send email and text notifications of events at the loading docks, such as truck arrival/departure, maintenance past due, after-hours activity, doors left open and more.

Systems, LLC

800-643-5424

www.loadingdocksystems.com

MACHINE VISION SOFTWARE

The EyeVision Machine Vision Software and EyeVision 3D Software from EVT, Germany, offers a variety of features, including:

- 3D capture and evaluation on the point cloud for e.g. pin inspection, bin picking, etc.

- 3D profile measurement for weld seam, adhesive bead and sealant inspection and more.

- 1D and 2D measurement and evaluation (support of numerous line scan and matrix cameras)

- Thermography capture and evaluation with special commands for active, passive and lock-in thermal imaging.

- Hyperspectral imaging capture and evaluation.

- Evaluation on color and gray scale images.

- Measurement and inspection technology.

- Surface inspection also with machine learning algorithms.

- Error detection

- Pattern matching

- Code reading.

- Object detection and counting.

- Position control.

- Color inspection.

- Contour inspection, etc.

EVT Eye Vision Technology GmbH

+49721 626905-82

www.evt-web.com

BEVERAGE, PAPER PRODUCTS & CARTON MATERIAL HANDLING SOLUTIONS

BOLZONI AURAMO Inc., Homewood, Ill., exhibited a number of beverage, paper products and carton material handling solutions, including:

Swing Frame Paper Roll Clamp - AMCS Series. This paper roll clamp boasts a 360-degree single-stage rotation unit and is equipped with a heavy-duty clamp body and arm design. This paper roll clamp includes built-in swing frame to effectively handle rolls also in confined spaces.

Carton and Appliances Clamp - LS-V Series. This carton clamp is designed for safe and damage-free palletless handling of white goods and high-volume carton boxes, such as warehousing and beverage industries. This innovative clamp has a new aluminum arm design with new high-friction rubber lining, and is with super grip-structured rubber, suitable for pallet handling.

Multi Pallet Handler - 12PH Series. Suitable for the lifting of pallets on both sides, either singly or two at a time, this multiple pallet handler can dramatically reduce handling time during storage or loading and unloading of vehicles. Plus, it is extremely durable thanks to its torsion-resistant steel profiles.

Fork Positioner – MZ Series. This wide range of fork positioners maximizes productivity, and the lightweight model enables the operator to position the forks directly from the driver seat.

180-Degree Rotating Paper Roll Clamp - ARC Series. Efficient paper roll handling with built-in damage prevention is a prime guideline. This ARC Series paper roll clamp is designed and engineered to have superior visibility, great rotating speed and be operator friendly.

360-Degree Rotator - RC Series. Suitable for all applications requiring rotation, the Bolzoni Auramo rotator features a safe castellated fork carriage with secure non-split fork locking. Plus, it’s easily adjustable by the operator and the operational speed at low oil volumes.

Lift Truck Forks. The Bolzoni Auramo forks are produced with innovative and highly automated production processes and are subject to a complete tempering heat treatment on the entire length of the forks. This, together with the prime quality steel and the high resistance to wear and corrosion, make these forklifts ideal for even the harshest environments.

In addition, Bolzoni Auramo announced plans to open a new and wider plant in Sulligent, Ala. The new 300,000-square-foot facility will be used to produce and assemble forklift truck attachments.

Bolzoni Auramo Inc.

708-957-8809

http://us.bolzonigroup.com

VERY NARROW AISLE HYBRID AUTOMATED GUIDED VEHICLE

Dematic, Grand Rapids, Mich., announced the North American availability of the Linde VNA (very narrow aisle) hybrid automated guided vehicle (AGV), powered by Dematic.

The Hybrid VNA is the result of joint development between Dematic and KION. KION Group, Summerville, S.C., acquired Dematic in November 2016.

In automated mode, the Hybrid VNA can drive, navigate and handle goods, including picking, putting, transporting and lifting pallet loads, without anyone in the driver’s seat.

Dematic

877-725-7500

www.dematic.com

SELF-DRIVING MATERIAL HANDLING VEHICLE

After nearly 35 years, ASI Technologies, Montgomeryville, Pa., rebranded itself as ASI Drives to better capture the company’s focus on delivering gear drive solutions.

ASI Drives also introduced FRED2500 AGV, self-driving, material handling vehicle.

FRED is simple to set up, productive, flexible and safe, offering multiple methods and opportunities to move material around the facility. Using empty dollies, a detachable handle and a quick-release tongue, FRED can easily move between multiple pickup locations with ease.

ASI Drives

215-661-1002

www.asidrives.com

ENHANCED CHECKWEIGHER

The Thermo Scientific Versa Flex FR44HD from Thermo Scientific, Minneapolis, is powerful checkweigher for the packaged food and warehouse industries, now with stainless-steel construction, a heavy-duty drive and enhanced user interface.

New features and benefits include:

- Heavy-duty drive standard across all FR44HD models for rugged performance, increased uptime and productivity; reliable handling of loads up to 110 pounds with speeds that can exceed 300 feet per minute;

- New control system for improved user navigation;

- Zoom weight feature displays numbers in a larger size, so users can view from a distance; and

- Stainless-steel construction for withstanding harsh cleaning agents.

The Versa Flex FR44HD checkweigher is also available in a warehouse version that can be integrated with material handling software for transmitting individual package weight to the manifest control system.

Thermo Fisher Scientific Product Inspection

763-783-2500

www.thermoscientific.com/productinspection

GEAR MOTORS, POWER TRANSMISSION PRODUCTS

Regal Beloit Corp., Beloit, Wis., featured its System Plast, SealMaster, Grove Gear, Hub City, McGill, Rollway and Browning power transmission products.

New are the Browning PE Series 3000 OtN gear motor with innovative tapered shaft connection, Klamploc adapter lock for SealMaster USRB bearings and Hub City Mod Drive gear and motor package, which bundles the Hub City HERA C-Face gear reducer with the Marathon ECM permanent magnet AC motor and mounted variable-frequency drive (VFD).

Regal also featured an expanded MODSORT modular transfer and diverter station, which eliminates the need for a lift or pneumatics, and can be easily integrated into new or existing material handling systems with the ability to transfer a wide array of products. It now offers the option to increase sort points faster and easier with the addition of two diverts.

The Klamploc adapter lock, designed with installation quick steps clearly marked on the collar to shorten set-up time, includes a clamping force, and the parts to not need to be removed or bent, allowing for a simple tightening process.

Regal Beloit Corp.

608-364-8800

www.regalbeloit.com

FLEXIBLE PICKING SOLUTION FEATURES INTELLIGENT MAPPING SYSTEM

Pcdata, East Granby, Conn., showcased Pickcarts, which are designed to improve pick rates and increase order accuracy in 3PLs, foodservice, retail and e-commerce applications.

Pcdata's Pickcarts are flexible, in that it’s easy to add or remove the number of pick lights and update smart tablet software.

They’re also efficient as an intelligent mapping system, preparing the most efficient route for the operator to walk. This modular picking system enables operators to simultaneously pick multiple customer orders.

Pcdata U.S.

855-844-1086

www.pcdata-logistics.com

INTEGRATED PUT WALL SYSTEM FEATURES ROBOTIC PIECE-PICKING SOLUTIONS

RightHand Robotics, Somerville, Mass., partnered with Capacity LLC, North Brunswick, N.J., to integrate robotic piece-picking solutions with technology-driven order fulfillment and e-commerce solutions.

RightHand Robotics’ newest RightPick product platform will also be integrated with existing warehouse material handling systems from Lightning Pick, a Waukesha, Wis.-based provider of light-directed and advanced order fulfillment systems.

RightPick is an autonomous robotic piece-picking platform that handles the core task of picking and placing individual items as part of a wide range of workflows and processes in warehouse fulfillment operations. Initially released to support AS/RS tending and sorter induction, RightPick’s put wall offering is capable of barcode identification, placement to a variety of compartments and integration with conventional put-to-light systems. It also allows conversion of existing manual put walls into robotic put walls.

RightHand Robotics, Lightning Pick and Capacity began collaborating in July 2018, with the integration of RightPick in Capacity’s New Jersey fulfillment center.

RightHand Robotics

617-520-4199

www.righthandrobotics.com

MODULAR SORTATION SYSTEM

GreyOrange, Atlanta, showcased its new Flexo modular sortation system and demonstrated upgraded versions of its Butler and PickPal solutions.

Flexo enables destination sortation, inbound and outbound, for fulfilment, distribution and logistics centers. Designed for flexibility, Flexo adapts to existing layouts, and can easily scale and handle versatile payloads without constraints to future growth. Flexo is also easy to deploy and portable across facilities. Capable of operating 24/7, this system reduces dependency on additional labor during peaks. Flexo components also allow for fast implementation in as short as 15 days, and can be easily scaled to handle large peaks.

GreyOrange

844-677-2237

www.greyorange.com

COLLABORATIVE ROBOT STATION

SNAP Resources (SNAP), a Fremont, Ohio-based unit of Motion Controls Robotics, displayed its mobile SNAPMate Station featuring a FANUC CR-15iA collaborative robot.

A SNAPMate Station with a FANUC Cobot provides manufacturers the tools and flexibility to increase productivity through the use of automation to accomplish a variety of smaller volume or short run applications:

- Machine tending - load and unload a variety of CNCs throughout the facility.

- Pick-and-place operations.

- Assembly.

- Inspection.

- Case packing.

- Palletizing.

SNAP simplifies cobot automation using the Ready Robotics Forge software and controller, which uses hand guidance with drag and drop programming.

Motion Controls Robotics

419-334-5886

www.motioncontrolsrobotics.com

LONG-STROKE GRIPPER

SCHUNK, Germany, debuted the Co-act EGL-C long-stroke gripper, what is said to be the world‘s first long-stroke gripper developed for collaborative operation.

This gripper achieves high gripping forces up to 450 N, and combines them with a long stroke of 42.5 mm per finger, making it suitable for handling workpiece weights of up to 2.25 kg.

The SCHUNK Co-act EGL-C gripper is equipped with a combined force-/path measurement. Force measuring jaws and an incremental encoder are integrated in the base jaws and permanently control the individual gripping forces and the position of the gripper fingers. The gripping procedure is stored in the gripper, and is divided into several phases.

An assistant simplifies programming during commissioning, and a diagnostic interface allows access to the main process and status data during the ongoing operation. The gripper is equipped with an LED light in traffic light colors that signals the current condition of the module, ensuring a smooth and intuitive collaboration with the operator.

Plus, the SCHUNK Co-act EGL-C can be controlled and adjusted via PROFINET, EtherCAT, EtherNet/IP, Modbus/TCP or TCP/IP.

SCHUNK GmbH & Co. KG

+49-7133-103-0

https://schunk.com

ROBOTIC ARMS FOR PICKING & PLACING

Boston Dynamics, Waltham, Mass., showcased Kinema Systems’ Pick technology, which uses a combination of vision sensors and deep learning software to work with commercial robotic arms in moving boxes from pallets to conveyors or building stacks of boxes on pallets.

Pick enables logistics, retail and manufacturing companies to achieve high rates of box moving with minimal setup or training for both multi-SKU and single-SKU pallets.

Boston Dynamics acquired Kinema Systems, Menlo Park, Calif., earlier this month.

Boston Dynamics

617-868-5600

www.bostondynamics.com

RUGGED HANDHELD TABLET

Handheld USA, Corvallis, Ore., showcased its new state-of-the-art Nautiz X6 ultra-rugged Android “phablet.”

The Nautiz X6 combines a conventional tablet with a traditional rugged handheld in a single device.

Ideal for rough-and-tumble applications, including utilities, foodservice, field service, warehousing, logistics and more, the superior u-blox NEO-M8N receiver makes for highly accurate navigation using GPS or Galileo. In the warehouse, read NFC tags or use one-button scanning to track virtually anything. The high-resolution rear/front cameras capture detailed images, and an array of sensors carry the load for a multitude of tasks.

The Nautiz X6 operates in extreme temperatures, handling drops, vibrations, humidity and altitude, and it’s fully dust- and waterproof.

Coupled with Handheld’s proprietary MaxGo software, this tablet can be used in a broad spectrum of communication technologies, including WLAN, cellular (WWAN), BT and NFC, and enables workers to connect with each other or the back office, sending, accessing and sharing data and reports seamlessly throughout the workday.

Handheld USA

541-752-0313

www.handheldgroup.com

HORIZONTAL MATERIAL HANDLING SYSTEM

Taylor-Dunn, an Anaheim, Calif.-based unit of Polaris Industries, provides a safer, more efficient horizontal material handling alternative for manufacturing and warehouse industries.

This tug system solution allows a single operator to deliver an increased amount of goods to multiple areas within the manufacturing or warehouse facility in one run using Taylor-Dunn tow tractors or stockchasers coupled with Jtec industrial carts from Jtec Industries, East Peoria, Ill.

The company’s patented CarryMore Mother/Daughter Tugger Cart Systems, along with its CarryLite towable carts and CarryMax Heavy-Duty Trailers, are capable of holding loads up to 30,000 pounds.

Taylor-Dunn, a Polaris Industries business

800-688-8680

www.taylor-dunn.com

WAREHOUSE EXECUTION SYSTEMS

Softeon, Reston, Va., demonstrated the flexible capabilities from the real-time control and optimization Softeon’s piece and case picking operation. This order fulfillment system is available as a part of Softeon’s Advanced WMS, or as a standalone shipping system. Benefits include optimized picking performance, with optimization tied to each specific picking technology, rapid implementation of new technologies, no interfaces to maintain, the ability to test new technologies before full commitment, robust exception handling and ability to scale technology support based on volumes.

Softeon also launched its new warehouse execution system (WES) capabilities, what is said to be the first in the industry to combine advanced WES and WMS solutions into one integrated offering. Softeon’s WES capabilities include:

- Strategic simulation tools to enable customers to performance test a WMS before go-live and to do "what-if" analysis to analyze gains from potential process or configuration changes before and after deployment.

- Tactical simulation tools to analyze resource requirements and potential throughput issues at the start of a day or shift.

- Automated order planning and release based on picking efficiencies and shipping times/customer service requirements, including full waveless picking.

- Management of order flow to minimize dwell times and keep materials handling equipment highly utilized.

- Real-time visibility to throughput and bottlenecks by individual processing of each area of the DC.

- The ability to plan human and equipment resource allocation based on actual and projected demand and to automatically re-allocate those resources as conditions change in the distribution center.

Softeon

703-793-0005

www.softeon.com

INTRALOGISTICS SOLUTIONS

The Raymond Corp., Greene, N.Y., unveiled its new intralogistics solutions designed to optimize a customer’s entire operation, create productivity and actionable insights through connectivity and transform operations through automation.

Automation solutions featuring the Raymond Courier 3030 stacker automated lift truck with Seegrid guided vision technology. The new Raymond Courier 3030 is a 2,500-pound-capacity automated stacker that combines Seegrid unparalleled guided vision technology with Raymond’s end-to-end warehouse solutions to automate end-of-line and pick-up and drop-off (P&D) applications. Ideal for handling and transporting goods between connected manufacturing and warehouse facilities, the reverse motion and auto-engagement functions optimize workflow and increase productivity. The Raymond Courier 3030 stacker automated lift truck also boasts a second-level vertical capability to reach heights up to 72 inches.

Zoning and positioning. Raymond’s zoning-and-positioning solution provides a fast and simple way to improve consistency, productivity and efficiency, helping minimize pick errors and variability through floor-embedded radio frequency identification reader (RFID) sensors that transmit instructions to a lift truck.

In-aisle detection system. Raymond’s in-aisle detection system, used in conjunction with wire guidance in very narrow aisles, is designed as a training reinforcement tool to provide notice of the proximity of a truck to certain objects and will decelerate a truck to a complete stop when such objects are detected.

Lithium-ion battery technology. Raymond’s single- and double-capacity lithium-ion batteries help customers enhance productivity and push operations to meet higher consumer demands, bringing steady performance throughout the duty cycle.

The Raymond Corp.

800-235-7200

www.raymondcorp.com

AUTOMATED CONVEYOR TRANSFER SOLUTION

The new automated conveyor transfer solutions from Omnia by Rotacaster, Australia, makes controlling parcels simple, fast and scalable.

At its core, the automated conveyor transfers feature Omnia wheels that, pound for pound, are said to be the toughest and best value omni-wheels available.

The all-polymer design makes them an ideal choice for any solution requiring high performance, reliability and resistance to a wide range of environmental impairments.

Omnia conveyor transfers enable the positioning, orientation, direction and locating of goods manually, semi-manually or automated.

Plus, the modular nature of the design allows installations to scale quickly and easily, tying into existing controls and systems or operating standalone.

Omnia by Rotacaster

+61 2 49 078 100

www.rotacaster.com.au

WEARABLE PRODUCTIVITY PLATFORM WITH AI DASHBOARD

Rufus Labs, Los Angeles, debuted Rufus Workhero, a wearable productivity platform equipped with a team AI dashboard.

The team dashboard offers managers full team visibility, worker performance metrics, safety incident management and team communication.

Meanwhile, the wearables provide hands-free mobility, improved task productivity, 99.9% accuracy and lightweight ergonomics for comfort.

Plus, this software offers team onboarding and unlimited upgrades.

Rufus Labs

415-758-0976

www.getrufus.com

AUTONOMOUS MOBILE ROBOT

Waypoint Robotics, Merrimack, N.H., launched MAV3K, a 3,000-pound payload omni-directional, autonomous mobile robot.

This industrial-grade autonomous mobile robot (AMR) comes equipped with Waypoint’s easy-to-use Dispatcher software, allowing it to be set up and autonomously operate in under 15 minutes. MAV3K’s safe and powerful batteries keep it moving through the longest workday. And, Waypoint’s EnZone wireless charging system enables MAV3K to charge itself.

Plus, MAV3K’s dual safety rated LiDAR sensors, 3-stage safety system and superior autonomous navigation ensures MAV3K will safely find its own way from Point A to B.

Waypoint Robotics

603-945-4040

https://waypointrobotics.com

IOT-ENABLED SUPPLY CHAIN SOLUTIONS

Barcoding, Inc., Baltimore, Md., exhibited the company’s innovative IoT-enabled supply chain solutions

For instance, Get Smart, the company’s latest mobile computer usage agent application, is designed to capture and report user and device usage information to provide real-time insight into when activities are performed throughout the day, on which devices and by whom.

Barcoding, Inc.

888-412-7226

www.barcoding.com

TEACHABLE COBOTS WITH HUMAN SENSE OF VISION

Productive Robotics, Inc., Santa Barbara, Calif., unveiled its full line of next-generation teachable collaborative robots (cobots) with an enhanced human sense of vision to its teach-and-learn platform.

The OB7-Max 8 and OB7-Max 12 cobots are equipped with the same “no programming,” simple-to-teach intelligence and human arm flexibility, designed to handle larger payloads with long reach at 8kg and 1700mmand 12kg and 1300mm, respectively.

Each OB7 model also boasts human-like sense of vision, which automatically learns to recognize and pick up objects with a single button push. By the end of this year, OB7 will also be equipped with an improved sense of touch.

Productive Robotics Inc.

510-777-0375

www.productiverobotics.com

AUTOMATED CARGO HANDLING CONVEYOR

The KEITH Freight Runner dock-to-trailer conveying system from KEITH Manufacturing Co., Madras, Ore., can reduce load/unload times from 45-60 minutes to under 5 minutes.

The Freight Runner dock-to-trailer conveying system integrates warehouse automation with shipping, addressing major issues associated with the loading and unloading of cargo at the dock. By seamlessly connecting the dock conveyor to the trailer conveyor, loading/unloading is both safer and faster. Personnel or equipment no longer need to cross the threshold of the trailer, eliminating confined space entry and reducing forklift damage to cargo or trailers.

The chain rail conveyor is designed to create seamless cargo transfer between dock and trailer. Installed in both the trailer and at the dock, it replaces the standard, manual process of cargo handling that includes a forklift operator and and/or an employee using a pallet jack. Once a forklift positions the unitized cargo onto the system during the loading process, the conveyor automatically indexes it forward. The Freight Runner system can move up to 30 tons of cargo at more than 30-feet per minute. The auto indexing function allows the operator to easily adjust the index length to accommodate the cargo size.

The KEITH Freight Runner system requires little or no facility or trailer modifications because it is designed to drop into place on a standard dock plate or in an existing trailer. The system also allows for a variation in trailer designs and heights without compromising reliability. It can be used in a variety of conditions and applications, from refrigerated trailers and warehouses to standard dry vans and open-air docks.

KEITH Manufacturing Co.

800-547-6161

www.keithfreightrunner.com

SUPPLY CHAIN SIMULATION & DESIGN

HighJump, Minneapolis, unveiled the latest for warehousing and logistics simulation and design.

HighJump CLASS enables end users to assess facility throughput and consider next-generation technologies and strategies to meet demands.

HighJump CLASS provides a virtual world for warehouse layout design and modelling to optimize the flow of goods. End users can tap into the capabilities of HighJump CLASS on their own, whenever needed. Businesses can evaluate future capacity requirements and the best technology choices for their needs, whether fixed automation like conveyors, flexible, next-generation digital technologies such as autonomous mobile robots or workforce-enabling solutions like voice. HighJump CLASS delivers quantifiable metrics, so businesses can anticipate how to handle new business models, a shrinking workforce, peak seasons and any other financial or organizational requirements.

HighJump CLASS is available as a stand-alone solution or an add-on to existing HighJump solutions.

HighJump

800-328-3271

www.highjump.com

LITHIUM BATTERY-POWERED MATERIALS HANDLING FLEET

Green Cubes Technology Corp., Kokomo, Ind., partnered with Preferred Freezer Services, Chatham, N.J., to launch what is dubbed as the largest lithium battery-powered fleet in the cold storage industry with approximately 9 megawatt hours (MWh) of capacity deployed.

Green Cubes Technology’s Lithium SAFEFlex battery systems save up to 65% on battery expenditures over 5 years and offer up to four times the longevity of lead-acid battery systems.

Other benefits include:

- 30% higher charging efficiency, allowing for increased productivity and less power consumption.

- Zero maintenance hassle since they are electronically monitored and equalized, and don’t require watering or cleaning of corrosive acids.

- Longer cycle life provides ongoing operations without battery swaps.

- Regenerative power avoids energy waste.

- Faster charging with a complete 1-hour recharge and no battery degradation.

Green Cubes Technology Corp.

502-416-1060

https://greencubestech.com

Preferred Freezer Services

973-820-4040

www.preferredfreezer.com

ROBOTICS PRACTICE HELPS COMPANIES OVERCOME LABOR SHORTAGES

enVista, Indianapolis, Ind., launched its new Robotics Practice to help companies overcome critical labor shortages in distribution and manufacturing.

The robotics solutions include proof-of-concept testing, operational assessments, modeling and analytics, custom test environments, automation assessments, tailored engineering solutions and a full robotics innovation and testing facility with Fanuc robots.

enVista Corp.

317-208-9100

www.envistacorp.com

LITHIUM BATTERY CHARGERS

Delta-Q Technologies, Canada, showcased its innovative ICL Series of lithium battery chargers – the ICL 1200 and the ICL 1500 in 85V and 120V models.

The 85V models are designed to charge lithium battery systems of any lithium ion chemistry from 14 to 24 cells in a series, while the 120V models can charge lithium-ion chemistries within 21 to 34 cells.

The ICL Series are IP66-rated to protect against dirt and fluids, and are designed to withstand severe on-board vehicle vibration, shock and temperature extremes.

The ICL series shares a set of standard features offering original equipment manufacturers (OEMs) with flexibility in design and deployment, including a wide AC input range, where any ICL Series charger can operate on any single-phase electrical grid around the world; a fully customizable, field replaceable cable design; and the ability to act as both an on- or off-board charger. The ICL Series is suitable for use on any electric machine, including light electric vehicles, lift trucks, unmanned aerial vehicles, scooters, aerial work platforms and sports and utility vehicles.

Delta-Q Technologies

604-327-8244

https://delta-q.com

SUPPLY CHAIN EXECUTION SOLUTION

Generix Group, Canada, showcased its enhanced, highly adaptable supply chain execution (SCE) solution Generix Supply Chain Hub.

Centered around extended WMS, manufacturing execution system (MES) and enterprise access management (EAM) capabilities, Generix Supply Chain Hub offers what is said to be the industry’s first feature-as-a-service platform.

From speedy implementations to streamlined integration of omni-channel online, automated and mechanized systems, Generix Supply Chain Hub keeps supply chains nimble, efficient and scaling, while ensuring execution excellence, compliance and operating stability.

Generix Group

514-938-4562

www.generixgroup-northamerica.com

TIRE COMPOUNDS

Trelleborg Wheel Systems, Wakefield, MA, displayed three new tire compounds, designed to provide increased productivity, safety, sustainability and value.

ProTEX, for instance, is an electrically-conducting, 100% non-marking compound engineered for use on material handling applications operating in potentially explosive environments. Compliant with EN1755 safety regulations and safer than fixed earthing strips, the ProTEX compound allows for material handling equipment to be used safely in applications where this is flammable gas, vapor or dust. ProTEX is also available with the Pit Stop Line feature, which indicates to operators and fleet managers when it’s time to replace tires.

The new heavy-duty compound ProHD is said to increase load capacity by as much as 15% for material handling applications. ProHD also increases driver safety, as it is engineered to enhance truck stability and prevent overloaded tires from cracking or melting. Restricting heat buildup in the tire, the ProHD improves fuel economy and battery life, and also features the Pit Stop Line function.

The new flame-retardant Heat Shield tire compound is designed to withstand the highest temperatures, eliminating the need for tire protection chains used in applications in the metal processing industry. Suitable applications for Heat Shield include wheel loaders, aluminum tapping vehicles, bath tapping vehicles, cavity cleaners, crust breakers and furnace charging vehicles.

Trelleborg Wheel Systems

800-548-8473

www.trelleborg.com