Innovations in Ice Cream Packaging

Packaging trends in ice cream reflect the broader F&B industry: supporting sustainability and ensuring product safety. Courtesy ljubaphoto / E+ / Getty Images

Ice cream manufacturers are continually evaluating packaging to meet changing environmental regulations and consumer expectations.

“People want to bring an out of home experience inside their homes, so delivering a premium packaging experience is top of mind. Artwork design, material selection and product experience are all critical,” said Patrick Goden, senior director of operations integration at Wells Enterprises, the largest privately held ice cream manufacturer in the United States. “Talking with consumers about what functionality they desire in both use and storage at home is key. Wells is always striving to improve the consumer/user experience minimizing waste in packaging materials and maximizing freezer space.

Overall, packaging trends in ice cream reflect those of the larger F&B industry: improving efficiency, supporting sustainability and leveraging automation for better operational control.

“The ice cream packaging industry is seeing several notable trends, particularly in retail and foodservice. Sustainability is a major focus, with companies increasingly using eco-friendly materials like paper-based wrapping material, compostable plastics and biodegradable options. There's also a strong emphasis on making packaging recyclable and reusable to reduce environmental impact,’ said Antonio Mundarain, processing manager of ice cream at Tetra Pak U.S. and Canada.

Food manufacturers are increasingly turning to paper-based alternatives to reduce environmental impact and be a part of a low carbon circular economy. But changing ice cream wrapping material is trickier than it seems. The most common new materials are more costly and the structure is completely different to plastic foil.

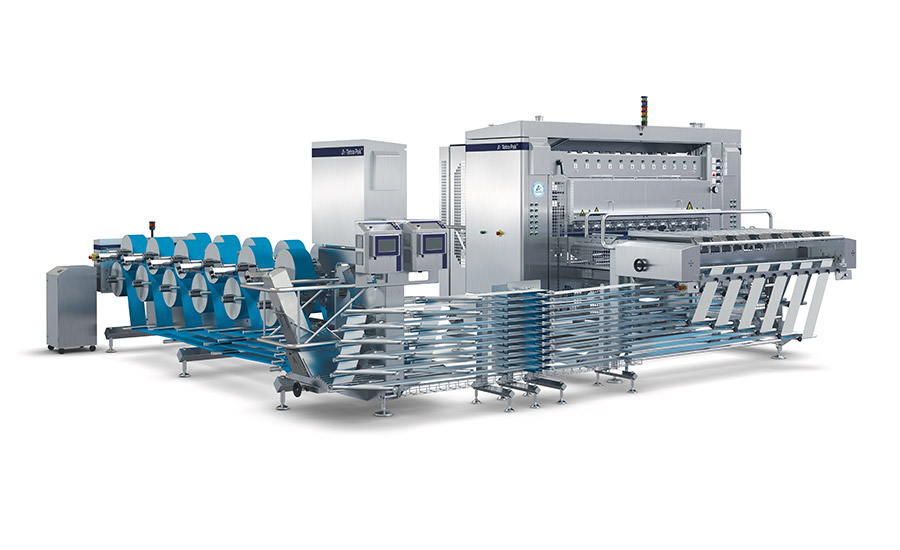

Tetra Pak’s latest innovation, a sustainable, paper-based wrapping material for ice cream, is designed to replace traditional OPP (Oriented Polypropylene)flow wrap. This new solution is optimized for compatibility with existing wrapping equipment and their new Multilane Wrapper A4, designed to work with a variety of packaging materials.

“Its patented tensioning control system allows it to handle a wide variety of wrapping materials, including paper-based and very thin plastic materials. This flexibility supports the use of more sustainable packaging options, reducing reliance on traditional plastics and enabling the use of more environmentally friendly packages,” Mundarain said. “The machine's high operational efficiency minimizes both product and wrapping material waste. By maintaining consistent performance and reducing downtime, it ensures that resources are used more effectively, contributing to overall sustainability goals. The ‘no product, no wrap’ functionality further enhances efficiency by preventing the creation of empty bags. This feature detects when a product is missing and temporarily stops the flow of wrapping material in that lane, thereby reducing unnecessary waste. With up to 12 lanes operating in continuous motion, this system ensures that only the necessary amount of wrapping material is used, aligning with sustainability objectives by minimizing excess waste.”

Multilayer structures, used for many years to prevent moisture migration in ice cream, can be challenging to sort at recycling facilities. Wells converted its 3-ounce cup, routinely sold in retail, from Polystyrene (PS) to Polypropylene (PP) and its 4-ounce Styrofoam cup sold in foodservice, to be more widely recycled, said Julee Zugel, director of strategic sourcing.

Innovia Films in July debuted a white ultra-low density film specifically engineered for ice cream flow wrap packaging. The high-gloss white, coextruded OPP film has a very wide heat seal range, suitable for ice cream sandwiches and popsicles. The films are largely unaffected by climatic conditions and if properly stored can be stored for a period of six months without any risk of deterioration.

Convenience and portability continue to drive changes in the design of both packaging equipment and materials.

“Single-serving sizes, such as pints and cups, are becoming more popular due to their ease of use and portion control benefits. Innovative designs are enhancing the consumer experience. Brands are offering customizable packaging to make their products stand out, and some are incorporating interactive features like built-in utensils or augmented reality elements to engage consumers. The rise of super-premium ice creams is leading to more luxurious packaging, with high-quality materials and sophisticated designs,” Goden said. “We do see innovative packaging machinery available in-market, but many times the machine can only complete one process. For large manufacturers such as Wells, having flexibility and multiple capabilities better supports on-going innovation efforts. Speed to market is key as well - the faster we can move together while ensuring equipment is thoroughly tested, the faster we can all benefit by meeting consumer’s needs.”

In other recent ice cream packaging news:

- Mini Melts, one of the fastest-growing frozen novelties in the U.S., in November announced a rebranding.

- Wild About Mixmi Froyo in the fall unveiled new packaging alongside a reformulated recipe aimed at gut health and immune function.

- Mars announced it will adopt use simulation software to help power packaging development. The food and pet care provider is redesigning over 12,000 packaging types across its portfolio to fit with the recycling infrastructure that either exists today or is likely to exist in the future.

- Chloe’s, BFY frozen novelty brand, in March expanded its product range and released redesigned packaging.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!